![]()

Email:

me

![]()

Delco Alternator conversion for a Spitfire

(a job now completed)

(this page last edited Wednesday,

January 22, 2014)

Note: This page will take some time to load

as to the large size of the photos!

Please be patient!

![]()

Photos below are of the original Lucas

alternator in place. It has given me no

problems that I know of. Perhaps we'll

find I had some once the Delco alternator is installed! I'm hoping my turn signals will blink faster

as described below by Michael!

Note that the fan belt is not in place. These photos were taken while replacing the

belt I had used for 15+ years which was always very loose and which I always

suspected of slipping. I took the belt

to Pep Boys and using the self-service size gadget, bought a belt that allowed

the proper tension when the alternator was almost at the furthest

adjustment. This is important for access

to the #1 spark plug. I didn't test this

yet. Keep your fingers crossed!

Note that this 1974 Spitfire is fitted with a

1968 1300+cc (modified) Mk3 engine to which is mounted the alternator from the

1974 1500cc engine I took out. (Actually, I must have replaced the alternator

at some point as it has openings for 2 separate connectors. I had modified the wiring and connected only

2 of the 3 wires in my harness to the Lucas unit. I must have a Lucas in my family tree!)

I am using a Delco alternator from my 1979

Camaro Z-28 as a guide for this conversion.

Project delayed

NOTE!

Well, I finally got the job done today,

The mounting bracket, a cast iron piece, was

drilled out to fit a 3/8” bolt as was used on the Delco. The swivel hole is that dimension. I bought a 4.5” bolt for that

application. It’s a tad too long, so I

bought 3 lock washers and 2 flat washers and a locknut to finish it off. Inserting the bolt from the distributor side

with a flat washer and the 3 lock washers on the head-end, it goes thru the

cast iron bracket, front engine plate, swivel flange on the Delco, another flat

washer and then the locknut.

Perfect! About one thread

protruding from the locknut.

I didn’t grind anything off the alternator

and used an alternator adjusting piece (flat with a slot for adjustment) I

picked up in the junkyard. I shimmed it

off the water pump housing about a half inch with some thick round washers

(what they really are is another story).

The fan belt lines up perfectly without any adjustments fore or aft. I used

an appropriately (1/2”) longer bolt to attach these items to the water

pump. Neverseize

the threads!

I was lucky to have just the right fan belt

so now I have perfect access to the #1 spark plug.

I connected the wires per #8 and #9 below.

Just for kicks in the process, I didn’t

attach the little brown wire, as I hadn’t used this on the Lucas

alternator. I started the car and

monitored the voltage at around 12. I

connected the little brown wire and the idle immediately went down a bit, the

engine seemed to be working somewhat and the voltage went to 14.4 demonstrating

that maybe Lucas wasn’t the real problem here.

I tried the turn signals and headlights.

The turn signals have suddenly come to life and the headlights don’t

look like daytime running lights anymore!

Big DUH! Voltage stable at 14.4

all the while. My old Spitfire had a

voltage gauge, perhaps I should install one in this car also!

I then took a 50 mile ride to charge up the

battery (I’m sure I’ve run it down somewhat, not adequately getting any

charge). It seems to run smoother and

have more power (and maybe even corner somewhat better)! Another DUH!

My favorite toy is getting better with age!

Next project is to install the newly rebuilt

calipers, pads and flexible hoses.

Anyway, I’m glad I finally got to this and

will post pictures soon!

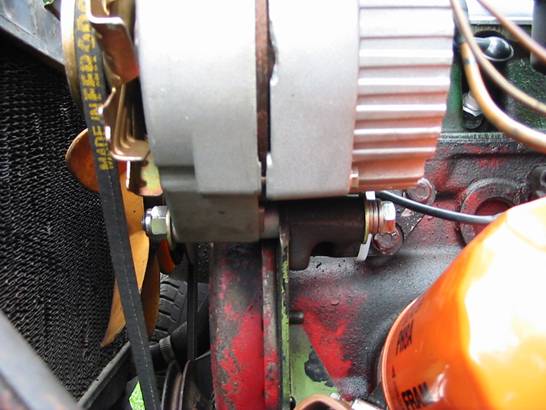

Lucas

alternator shown.

Cast iron bracket (which I drilled larger) shown to rear (right) of front

engine plate below the alternator.

Tight

fit getting to #1 spark plug.

![]()

now

for the Delco pictures…

![]()

The

“patina” of the engine has recently changed, what you see here is now

gone! 20+ years of rust preventative are

now killing mosquitoes in the wetlands!

See the section (soon to be added) on installation of the oil line to

the cylinder head.

Delco

unit installed. Easy access to the #1

sparking plug.

Delco

unit in place.

Bottom

support bolt with 3 lock/spring washers and a flat washer on bolt-head end, a

locknut on the other end with a flat washer also.

Spacers

on water pump bolt to hold alternator bracket. A new bolt ˝” longer is

used. Never-seize on the threads, of

course!

![]()

email from the Spitfire email list detailing the Delco alternator

installation that I am used as a guide:

Subj: Midget 1500 (Spitfire)

Alternator Conversion Completed

Date:

From: michael.graziano@csfb.com (Graziano, Michael)

Sender: owner-spitfires@autox.team.net

Reply-to: michael.graziano@csfb.com (Graziano, Michael)

To: spitfires@autox.team.net

('spitfires@autox.team.net')

All,

I bit the bullet and converted the Midget to

the GM 7127 unit. I believe I used a '78

LaSabre as the PC lookup in the auto parts store. The 7134 also works, but is an 80amp unit

versus the 63amp unit I bought. It was

$40 more.

Parts needed:

1) Alternator - $39.99 plus $15 for the core

charge. It's a lifetime warranteed

DuraLast from AutoZone. Note: I got the

one with the

2) The GM alternator harness plug was 2.39 in

the wiring section.

3) 7" chrome alternator bracket

4) 2 wire connectors (blue for medium sized

wires) to connect two wires.

5) One yellow (large) wire connector with a

circle connection for mounting on a stud on the alternator.

The methodology:

1) Removed the old alternator and both

brackets.

2) Install bottom alternator bracket from a

'75 spitfire. This is the same as the

'78 Midgets, only the portion that mounts to the alternator on the '78 install

is removed. This is essentially a

brace. Picture the solid piece with the

2 boltholes for the block, and the 1" thick hole that mounts to the front

engine plate. The 3" long hole

where the old alternator fits was never cast on this bracket. I think it had something to do with the air pump.

3) Grind off the small lip on the bottom of

the GM alternator. You'll see where it

interferes with the front engine plate.

I used a Dremel and 3 heavy-duty grinding disks. It's a clean enough job that no one will

notice if I ever have to return it. A

hacksaw would have sufficed.

4) Mount the bottom of the new alternator to

the front of the engine plate opposite the bracket you just installed. One bolt goes through the alternator, the

engine plate, and the bracket.

5) Take the old top alternator bracket to the

workbench. Cut off the round loop

section that was previously used to pull the engine. I'll have to find another method when I have to

pull it for the clutch. Also trim the

bend where it interferes with the water pump housing for the method I needed to

install it (see below)

6) Replace the old bracket backwards so that

the bend which previously moved the adjustment section of the bracket towards

the front of the engine bay, now moves it towards the back of the engine bay

(but still pointing towards the driver's side of the car (left hand drive).

7) Install the 7" bracket to the

alternator mounting hole on the top. Install it to the old top bracket. They should line up perfectly. Install the

stock belt, tighten it to spec, and tighten all the bolts.

8) Cut

off the old Lucas alternator harness.

Leave about 2" of wire on the harness in case you ever use drugs

and want to reverse this conversion.

Note: My harness had three

wires. A small gauge solid brown wire, a

small gauge brown and yellow wire, and a large gauge solid brown wire.

"The large Brown wire is the main charging lead. The smaller Brown wire

measures the system voltage to tell the alternator how much to charge. The

Brown/Yellow wire operates the alternator warning light, and provides the

initial voltage to the alternator to start it charging when the engine first

starts," (Dan Masters).

9) Connect the brown and yellow wire to the

#1 wire on the harness plug. The wire number is marked on the alternator, and

the plug is keyed so it can only be installed in one direction. Connect the small solid brown wire to the #2

wire on the harness plug. Connect the

large solid brown wire to the yellow connector, and bolt the yellow connector

to the stud protruding from the back of the alternator housing. The alternator comes with a nut to bolt the

wire down. Make sure you use dielectric

grease on the connections to prevent corrosion.

10) Make sure all the bolts are tight, all

the connections are done, and that the belt is tight and lined up correctly

with the crank and the water pump. It

should be.

11) That's it. Start the car, hook up a volt gauge, and see

the system charge at 14 volts.

My blinkers (which had all the switches and

connections cleaned a few weeks ago) now go "click click click click

click" rather than "click...........click..........click....."

At night with the lights on, the radio on,

the wipers on (fast), the vent fan on, and the hazards on I still had plenty of

charging power. Nice. Very nice.

Michael

'78 Midget

![]()

Email:

me

-----

-----

![]()